Segments

Automotive

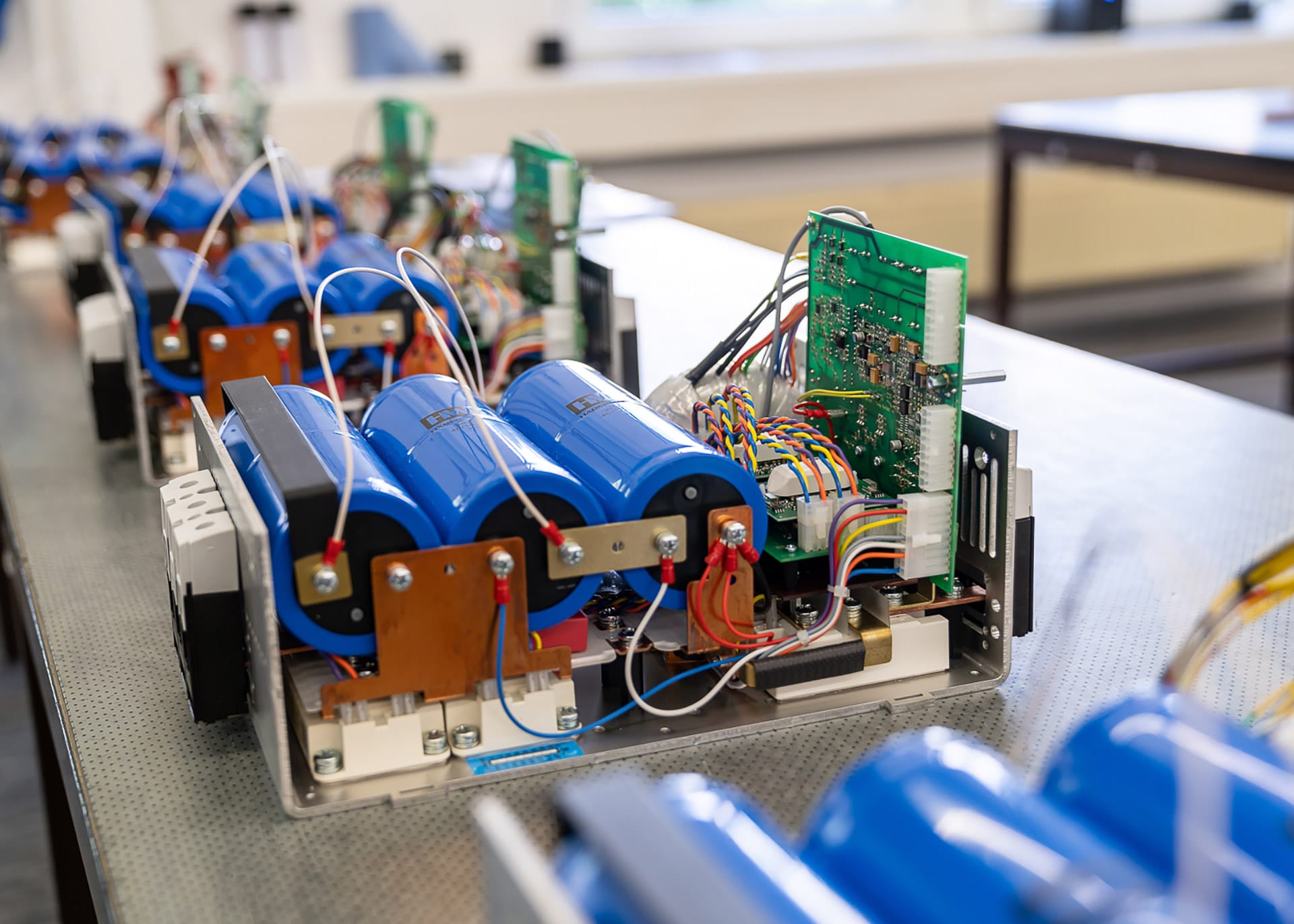

Efficient and safe automotive production requires state-of-the-art materials that call for welding technology that is as flexible as it is precise. At the same time, the systems must be easy to operate and feature a high degree of robustness to ensure trouble-free processes. Harms & Wende masters this balancing act with high-quality product lines that are optimally tailored to the special requirements of automotive production.

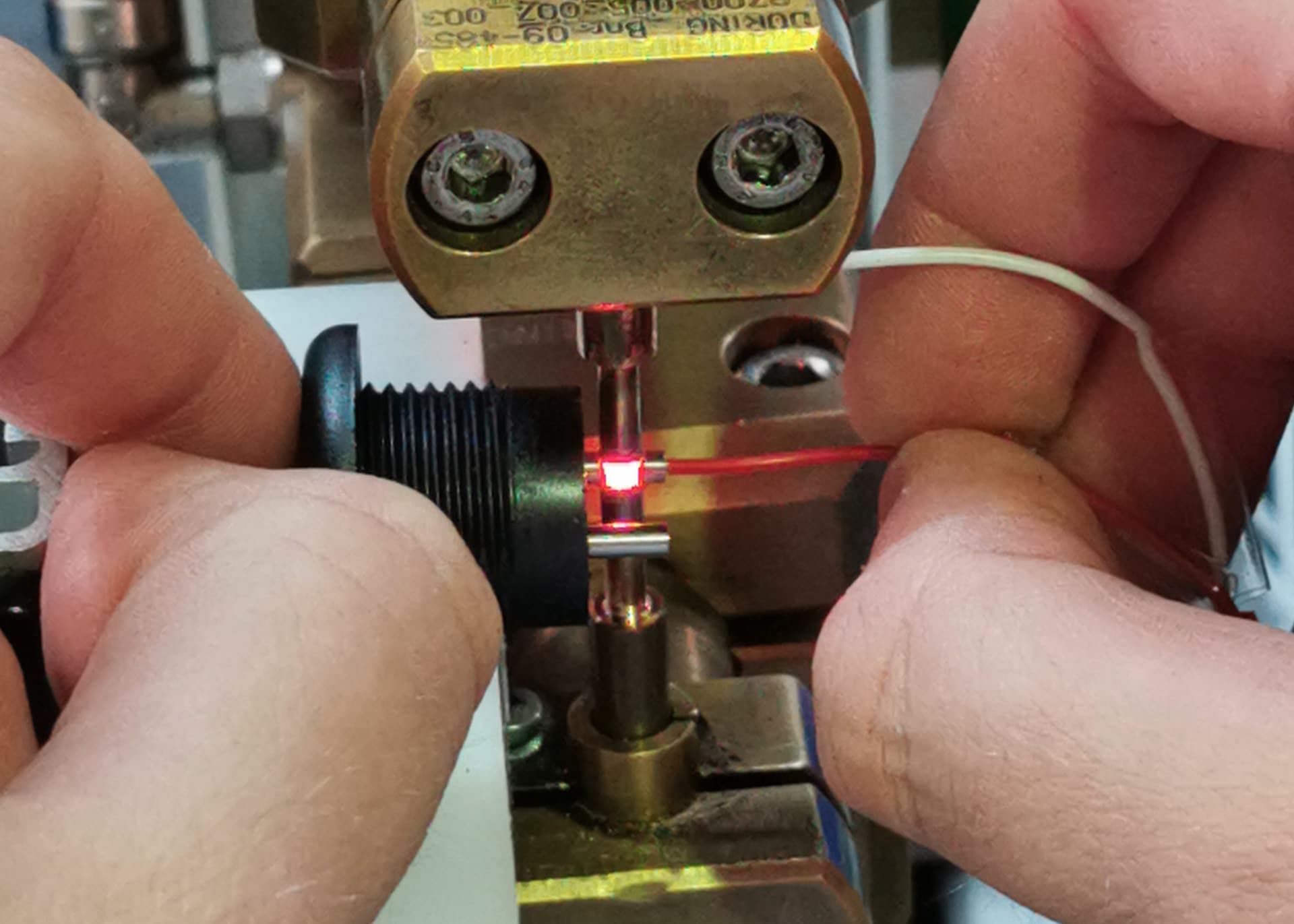

Innovative solutions for robotic guns, automated welding cells and classic manual systems – perfect joining and Industry 4.0The economy is on the threshold of the fourth industrial revolution. Driven by for steel and aluminum.

From manual systems to fully automated systems with BUS connections to cross-system networking and archiving, we offer a wide range of individual solutions for the automotive sector. Available are welding systems for use in the context of Industry 4.0 as well as classic manual systems.

Hot-formed steels, coated sheets and aluminum – with Harms & Wende welding controllers you have all materials under control.